DTC P055F:00

Engine oil pressure control circuit low oil pressure

DETECTION CONDITION

TYPE A (PCM part number: SHAG-188K2-A—B, SHAH-188K2-A—C, SHAJ-188K2-A—B, SHAK-188K2-A—B, SHAM-188K2-A—B, SHAN-188K2-A—B, SHAP-188K2-A—C, SHAS-188K2-A—B, SHAV-188K2-A—B, SHAW-188K2-A—C, SHCE-188K2-A—B, SHCF-188K2-A—B, SHBX-188K2-A—C, SHCB-188K2-A—B, SHCC-188K2-A—B, SHCD-188K2-A—C, SHEH-188K2-A—B)

• The engine oil pressure is the specified value or less after the specified time has elapsed since the engine was started.

-

― Engine speed is 2,000 rpm or less: 80 kPa {0.82 kgf/cm2, 12 psi}― Engine speed is 2,000 to 3,500 rpm: 120 kPa {1.22 kgf/cm2, 17.4 psi}― Engine speed is 3,500 rpm or more: 180 kPa {1.84 kgf/cm2, 26.1 psi}

TYPE B (PCM part number: except SHAG-188K2-A—B, SHAH-188K2-A—C, SHAJ-188K2-A—B, SHAK-188K2-A—B, SHAM-188K2-A—B, SHAN-188K2-A—B, SHAP-188K2-A—C, SHAS-188K2-A—B, SHAV-188K2-A—B, SHAW-188K2-A—C, SHCE-188K2-A—B, SHCF-188K2-A—B, SHBX-188K2-A—C, SHCB-188K2-A—B, SHCC-188K2-A—B, SHCD-188K2-A—C, SHEH-188K2-A—B)

• The engine oil pressure is the specified value or less after the specified time has elapsed since the engine was started.

-

― Engine speed is 2,000 rpm or less: 105 kPa {1.07 kgf/cm2, 15.2 psi}― Engine speed is 2,000 to 3,500 rpm: 120 kPa {1.22 kgf/cm2, 17.4 psi}― Engine speed is 3,500 rpm or more: 180 kPa {1.84 kgf/cm2, 26.1 psi}

Diagnostic support note

• This is a continuous monitor (CCM).

• The check engine light illuminates if the PCM detects the above malfunction condition during the first drive cycle.

• FREEZE FRAME DATA/Snapshot data is available.

• DTC is stored in the PCM memory.

FAIL-SAFE FUNCTION

• PCM restricts engine torque.

• The fast idle up correction for the idle speed control is inhibited.

POSSIBLE CAUSE

• Engine oil leakage

• Improper engine oil level

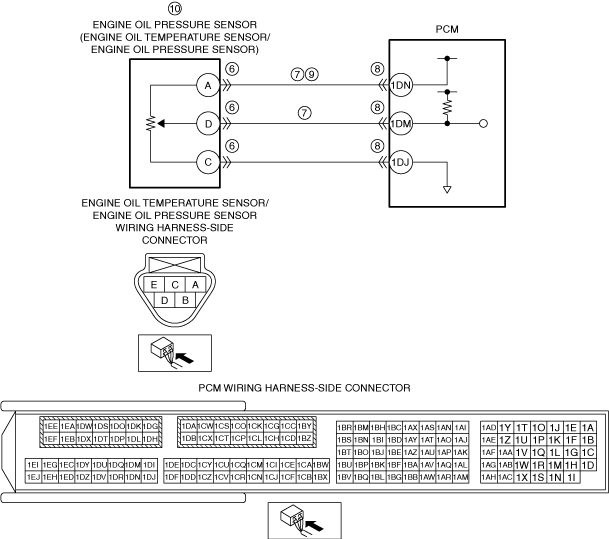

• Engine oil temperature sensor/engine oil pressure sensor connector or terminals malfunction

• Short to ground in wiring harness between the following terminals:

-

― Engine oil temperature sensor/engine oil pressure sensor terminal A—PCM terminal 1DN― Engine oil temperature sensor/engine oil pressure sensor terminal D—PCM terminal 1DM

• PCM connector or terminals malfunction

• Open circuit in wiring harness between engine oil temperature sensor/engine oil pressure sensor terminal A and PCM terminal 1DN

• Engine oil pressure sensor malfunction

• Oil strainer clogging

• Oil pump malfunction

• PCM malfunction